As a sales of

optical transceiver should know that the operating temperature will influence the parameters of the optical transceiver. According to the working temperature, there are industrial and commercial optical transceiver. What is industrial and commercial optical transceiver? What are their differences?

1. Working temperature

Commercial optical transceiver: 0~70℃

Industrial optical transceiver: -40~85℃

2. Application environment

Commercial optical transceiver: It is the most common and widely used product in the market, such as the machine room.

Industrial optical transceiver: It is applied in a relatively harsh environment,the operating temperature difference is large. It’s basic operating condition is that it must meet the temperature requirement of - 40 ~ 85 ℃. Such as remote mountain areas, tunnels, etc..

3. Chip withstand temperature

Commercial optical transceiver: The withstand temperature range of TO-CAN is 0~70℃.

Industrial optical transceiver: The withstand temperature range of TO-CAN is -40~85℃.

4. Test method

Commercial optical transceiver: Normal temperature aging, the maximum temperature is only 70 degrees, the ideal operating temperature is 0~70℃.

Industrial optical transceiver: Need high and low temperature aging test, the maximum temperature is 85℃, the module can work steadily less than 0℃.

5. Temperature compensation software

Industrial optical transceiver must be imported temperature compensation software, it’s function is to control the stable working current supply of the optical transceiver. When the temperature changes,the temperature compensation software will play it’s role.

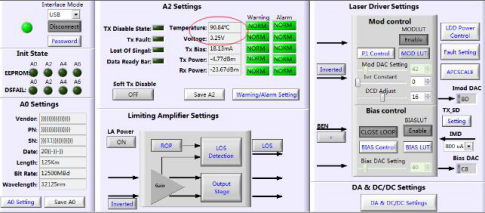

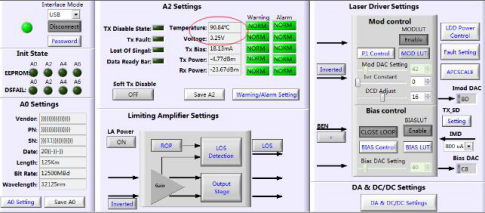

The technical engineer needs to spend much time to do the temperature compensation. Increase or decrease every 5 degrees(or 10 degrees) as a node to calculate it’s slope. They need to write into to the corresponding IC(chip) of the optical transceiver after get the result. This work makes the technical engineer have to stay in front of the high and low temperature cycle aging box for a few hours or even longer. The increase in the raw material and the making cost, which is the cause of the high price of the industrial optical transceiver. The compared pictures of the working current before and after temperature compensation:

ETU-Link as a professional manufacturer of optical transceiver, we are not only work hard on the selection of raw material for all industrial optical transceiver products,but also technically fuss(temperature compensation), to guarantee that our industrial products can maintain the normal transmission in the harsh environment.

Thank you for your patience to read, hope this article can help you! If want to know more about industrial products, please click on this link!

http://www.etulinktechnology.com/blog/the-industry-optical-transceiver_b17