What test procedures are required for high-quality optical modules?

Optical modules will go through strict testing and quality inspection procedures before shipment, such as material testing, parameter testing, aging testing, real machine testing, end-face testing, etc. The results of all test items must reach the standard level, otherwise the optical module will be returned to the production line to re-adjust. Understanding these tests will help you distinguish the quality of the optical module. In this article, ETU-LINK will reveal the important tests that high-quality optical modules must pass, and the impact of these test results on the quality of optical modules.

1. Material testing and Surface Mounted Technology(SMT) inspection

ETU-LINK will conduct material testing and SMT inspection before assembling the optical module. Among them, the material testing refers to the manufacturer's inspection of incoming devices before assembling the optical module, such as detecting whether the optical transmitting assembly (TOSA), the optical receiving assembly (ROSA), and the optical transmitting and receiving assembly (BOSA) are qualified, so as to ensure that the optical module’s quality, reduce rework rate and defect rate, while avoiding damage to expensive optical components. The SMT detection is mainly to detect whether the PCB board SMT is correct and whether there is pollution, so as to ensure the performance of the optical module.

2. Optical power detection

The average output optical power is an important parameter of the optical module, which directly affects the communication quality.

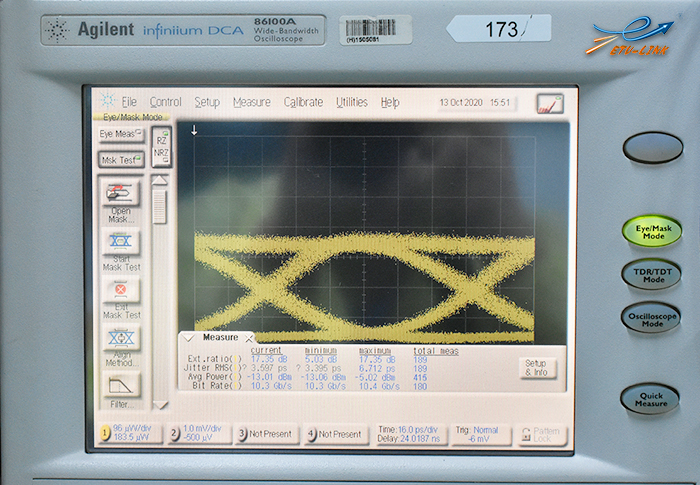

3. Extinction ratio and Optical Modulation Amplitude (OMA) test

The extinction ratio is one of the parameters used to measure the quality of the optical module. The extinction ratio refers to the ratio of the optical power of the laser output at high level (ie all "1" codes) and low level (ie all "0" codes). The test can detect whether the laser is working within the best bias point and best modulation efficiency range. In addition, the optical modulation amplitude (OMA) is also an indicator of the power difference when the laser is turned on and off.

Both of these are detected by mainstream optical oscilloscopes. At the same time, in the extinction ratio detection, the relative amplitude of the optical signal "1" level and "0" level can be seen. The larger the extinction ratio, the greater the relative amplitude, and the stronger the optical signal can be distinguished and received, and the sensitivity will be higher. Meanwhile, the extinction ratio is inversely proportional to the optical power. During the test, it can be found that the greater the extinction ratio, the smaller the emitted optical power.

4. Bit error rate and receiving sensitivity test

The bit error rate is one of the parameters that measure the ability of an optical module to correctly transmit symbols. The bit error rate refers to the ratio of the number of error code elements received after the photoelectric conversion of the receiving end within the specified time to the number of code elements given by the output end of the error meter. The error rate test requires that the optical signal with pseudo-random signal output of the tested optical module be received by the standard receiving tube test unit. Simultaneously, the standard receiving tube test unit is used to perform comparison after demodulation to complete the bit error rate test.

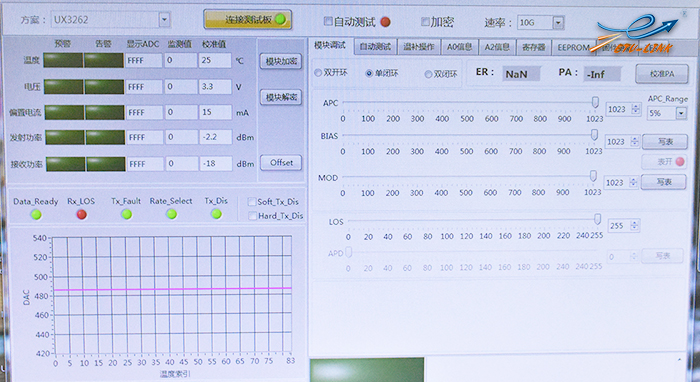

5. Eye-Diagram testing

Eye diagram testing and adjustment is an important stage to ensure that the optical module obtains the best signal. The so-called eye diagram is formed by superimposing and accumulating all captured waveforms in every three bits through the afterglow function of the oscilloscope. The digital signal quality of the optical module can be seen from the eye diagram test results. By carefully observing the eye height, eye width, jitter, duty cycle, etc. are used to judge the performance of the optical module. The larger the eye, the smaller the crosstalk between codes and the better the performance of the optical module.

6. Wavelength test

Since the optical modules used on the devices at both ends must emit the same wavelength to establish communication, the manufacturer must test the wavelength of the optical module before shipment to ensure that it is within the deviation range.

Generally, manufacturers use spectrum analyzers and other instruments to measure the central wavelength of optical modules, and the measured central wavelength value of optical modules usually deviates from the standard value. Different types of optical modules have different deviations, but as long as the deviation is within the allowable range If the test value is inconsistent with the standard specification, the optical module is regarded as defective.

Manufacturers generally use optical aging boxes to simulate extreme conditions to test optical modules to verify whether the performance of the optical modules meets the standard. After the aging test is completed, the transmitter and receiver need to be tested, mainly to check whether parameters such as optical power, extinction ratio, and sensitivity meet the requirements.

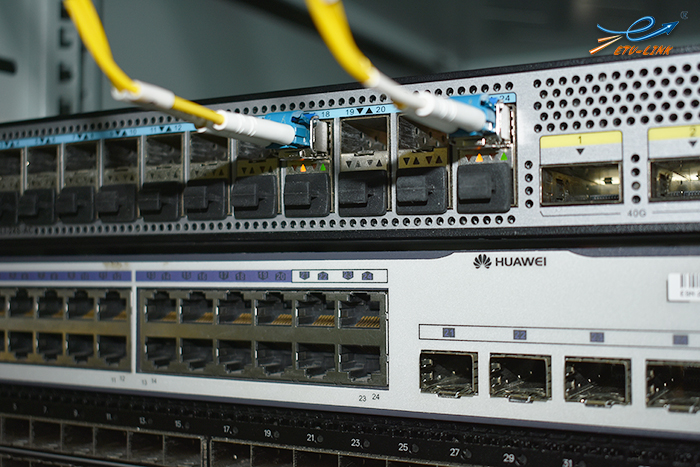

8. Compatibility testing

We need to insert the optical module into the switch of the corresponding brand for testing. If the communication is normal, it means that the optical module has passed the test. If it is unable to communicate, it means that the optical module is not compatible with it.

9. End-face testing

After the optical module passes through each test item, it is necessary to check whether there is dirt and scratches on the end face of the module through a microscope. If there is dirt, it needs to be cleaned. In fact, every test item involves inserting the optical module into the device or instrument, so that the optical module is easily contaminated. Therefore, it is necessary to place the optical module under a microscope for inspection before shipment.The goods can be packed and shipped without dirt, but if there is dirt, it needs to be cleaned.

The above-mentioned tests are all required by qualified optical transceiver manufacturers. ETU-LINK strictly controls the quality of optical modules and will pass the above-mentioned tests before shipment. You can buy with confidence.

Categories

New Blog

Tags

© Copyright: 2026 ETU-Link Technology CO ., LTD All Rights Reserved.

IPv6 network supported

Friendly Links:

易天官网