Comparison of COB Packaging vs. Coaxial Processes in Short-Distance Optical Modules

In the field of short-range optical communication, the packaging technology of optical modules directly affects product performance, cost, and application adaptability. COB (Chip On Board) packaging and coaxial technology, as two mainstream technologies, differ significantly in structural design and performance. This article will analyze the differences between the two from key dimensions to assist industry selection decisions.

The most obvious difference between the two lies in their structural design.

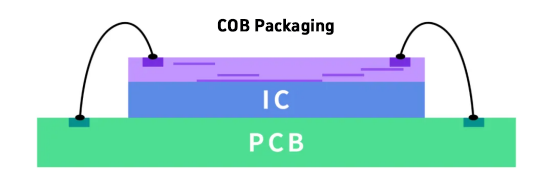

COB packaging involves directly mounting the optical chip and driver chip onto the PCB board, achieving electrical signal interconnection through gold wire coupling. This eliminates the need for an additional packaging base, resulting in a compact overall structure.

In contrast, coaxial technology centers on a coaxial connector, with optical devices encapsulated within a metal or ceramic substrate. Signals are transmitted via coaxial cables, leading to a more modular assembly structure with independent signal transmission channels.

In terms of performance, the two technologies have their respective strengths.

COB packaging, due to direct chip mounting, has a shorter signal path, lower insertion loss (typically 0.3-0.5dB lower than coaxial technology), and better heat dissipation efficiency, making it suitable for high-frequency, high-power, short-distance transmission scenarios (such as 100G/200G data center interconnects).

Coaxial technology, on the other hand, benefits from the shielding properties of its coaxial structure, offering stronger resistance to electromagnetic interferenceand outstanding signal stability. It is more advantageous in complex electromagnetic environments (such as industrial control scenarios), but its performance advantages are difficult to fully realize when the transmission distance is short.

The differences in cost and mass production efficiency are significant.

COB packaging simplifies the assembly process, reduces the use of components such as bases and connectors, lowers material costs by approximately 15%-25%, and is suitable for large-scale automated production, resulting in higher mass production efficiency.

Coaxial processes involve the assembly of precision components, requiring higher production accuracy, and have higher material and labor costs, making them more suitable for small-batch, customized needs.

The application scenarios are different.

COB packaging has become the first choice for large-scale short-distance interconnection scenarios such as data centers and cloud computing due to its high cost performance and high integration.

While coaxial technology is more widely used in short-distance transmission scenarios with strict environmental adaptability requirements, such as industrial optical communication and automotive optical modules, due to its strong stability and good anti-interference.

In summary, the differences between COB packaging and coaxial technology for short-range optical modules lie in four main dimensions: structure, performance, cost, and application scenarios.

When selecting a solution, it's crucial to consider actual needs.

If high cost-effectiveness and mass production efficiency are prioritized, COB packaging is the better choice.

If interference resistance and environmental adaptability are emphasized, coaxial technology offers greater advantages.

Categories

New Blog

Tags

© Copyright: 2026 ETU-Link Technology CO ., LTD All Rights Reserved.

IPv6 network supported

Friendly Links:

易天官网